INTRODUCTION

Surface irrigation is the most used system, occupying the immense majority of the lands of irrigable at world level (Sánchez et al., 2002). Superficial irrigation in Cuba occupies 71% of the irrigated total area and it is in a critical technological state due to the absence of improvement investments (Pérez et al., 2013).

Superficial irrigation is intrinsically less efficient than the aspersion and the drip, because losses for deep percolation and runoff are inevitable (Génova et al., 2014); but the design and appropriate management allows the efficient and uniform irrigation of the lot (Faci & Playán, 1996; González & Playán, 1996).

In many countries of the world, the investigations are carried out with the purpose of replacing the furrows irrigation for pressure methods; however, the economic-financial situation of the producers restricts in many occasions the possibility of carrying out this technological exchange rate. Hence, the potential alternative is the superficial irrigation (Durán & García, 2007).

The knowledge of the relationship between soil type, water and cultivation allows the application of water in convenient quantities, according to the irrigation system to be used. That is why water measuring is essential for the maximum use of the resource Carrión (2015). On the other hand, it is necessary that the farmer familiarizes with the terms associated with the mensuration of the inflow rate (Bello & Pino, 2000).

Irrigation design consists on determining the optimal inflow rate and the time during which this flow is applied in the head of the field to achieve the biggest possible uniformity of application, for a longitude and a particular soil type (Saucedo et al., 2013). The objective of the present work consists on evaluating a methodology proposed to estimate the furrow inflow rate from Chezy and Bazin’s Equations.

MATERIALS AND METHODS

The investigation was developed in a lot of sugar cane of the variety C-120 located in the block 609 of the Basic Unit of Cooperative Production (UBPC) Albio Hernández of Primero de Enero Sugar Company, in Ciego de Ávila province. The irrigation system used is the type furrows irrigation, by means of pipes with multiple floodgates formed by a buried pipe of PVC with diameter of 315 mm that goes out directly of the station of pumping with a maximum longitude of 500 m in which the valves that supply water to the irrigation pipes of PVC with diameter of 280 mm are placed. This has adjustable floodgates every 1.50 m for the discharge of the furrow inflow.

Maximum height of the furrow (y max ), maximum top width (T max ) and bottom (b) were measured under experimental conditions in nine furrows selected at random inside the study area; later the furrow side slope coeficient was obtained by means of the following equation:

Furrow inflow rate was measured to the exit of the floodgates by means of the volumetric method; then, they were measured the times in which, the front of advance of the water flow, reached the stakes placed every 20 meters on the total furrow length of 100 m and average slope of 4.0‰. A digital chronometer of one-second accuracy was used. In these points, the value of top width (T i ) and flow depth (y i ) that allowed finding an adjustment model to estimate the flow depth in function of the top width of the water, were also obtained.

Validation of the statistical models was carried out by means of the Coefficient of Determination (R 2 ) according to Vicente et al. (2003) and the Half Percentage Error (Zúñiga & Jordán, 2005), with series of different data used properly for the generation of the model and the prediction. The equation used was the following:

Where APE is the Average Percentage Error (%); n the number of data of the series; y obs the observed variable; y sim the predicted variable.

The methodology proposed in this investigation is composed of the six following fundamental procedures. (1) Practical determination of the side slope coeficient of the irrigation furrows. (2) Determination of model that relates flow depth with the top width of the water in the furrow. (3) Obtaining of the coefficients μ and ξ to estimate the cross sectional area of flow, the wetted perimeter and the hydraulic radius of the furrow. (4) Estimating the speed of the water in the furrow irrigation according to the equation of Chezy and the coefficient of speed for the equation of Bazin. (5) Calculation of the furrow inflow rate by means of the equation of continuity. (6) Validation of the methodology proposed through the comparison between the furrow inflow rate real applied and the predicted ones.

RESULTS AND DISCUSSION

Analysis of Side Slope Coeficient in the Irrigation Furrows

Table 1 shows the values of geometric parameters of the furrow obtained directly in the different samplings points established in the experimental area. In Table 2, the main statistics corresponding to the descriptive analysis are shown. There, the mean values of the maximum height, maximum top width, bottom, and side slope were 0.159 m; 0.590 m; 0.032 m and 1.756, respectively, for what they should be taken as definitive design parameters for the specific conditions of this productive system.

TABLE 1.

Parameters measured in the furrow for determining the side slope coefficient

| No. | y max (m) | T max (m) | b (m) |

|---|---|---|---|

| 1 | 0.160 | 0.600 | 0.028 |

| 2 | 0.165 | 0.600 | 0.033 |

| 3 | 0.160 | 0.585 | 0.035 |

| 4 | 0.150 | 0.563 | 0.024 |

| 5 | 0.140 | 0.570 | 0.042 |

| 6 | 0.170 | 0.614 | 0.030 |

| 7 | 0.154 | 0.580 | 0.030 |

| 8 | 0.166 | 0.610 | 0.029 |

| 9 | 0.170 | 0.587 | 0.037 |

TABLE 2.

Descriptive Statistics of geometric parameters of the furrow

Obtaining of the Model that Relates Flow Depth with Top Width in the Furrow

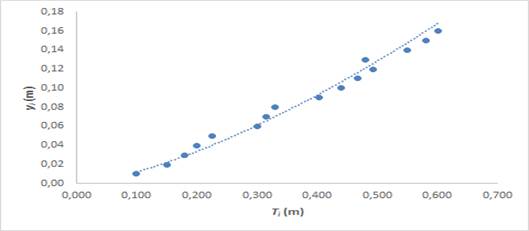

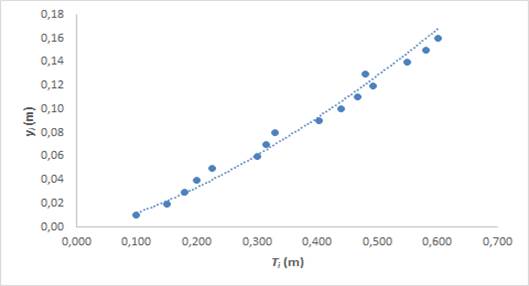

The behavior of the flow depth and the top width of the water on the furrow are presented in the Figure 1. These variables were adjusted appropriately to a model of simple potential type with a high coefficient of determination of 0.980; consequently, they can be used in a reliable way for estimating the flow depth in the furrow irrigation. This result is very important because it avoids the mensuration of the flow depth that is more annoying and inexact. The found model was the following:

FIGURE 1.

Curves of the flow depth in function of top width.

Deduction of the Equation for Estimating Cross Sectional Area of the Flow in Furrows

The equation proposed in this investigation for estimating cross sectional area of flow in the furrow was sustained in the values of bottom width (b), top width (T), flow depth (y) and furrow side slope found experimentally. The sequence used for its deduction is presented next:

Substituting Equation (5) in (4) and clearing the parameter b, it is obtained:

Cross sectional area of flow in the furrow was assumed according to Cadavid (2009), as:

Substituting Equation (6) in (7), it is obtained:

Developing the previous equation is:

Cross sectional area of flow in function of the coefficient μ is obtained by means of the common factor:

Deduction of the Equation for Estimating Furrow Wetted Perimeter

The wetted perimeter of the furrow was determined according to expression suggested by Cadavid (2009), which is written in the following way:

Substituting Equation (6) in (11), it is obtained:

Wetted perimeter in function of the coefficient μ is obtained by means of the common factor:

Deduction of the Equation for Estimating Furrow Hydraulic Radius

Hydraulic radius of the furrow was determined as the quotient between cross sectional area of flow and wetted perimeter Gribbin (2016); this is:

Substituting Equation (10) and (13) in (14), it is obtained:

Simplifying, it is obtained:

The coefficient ξ is written in the following way:

Substituting Equation (17) in (16), the hydraulic radius is calculated in function of the coefficient ξ and flow depth of water in the furrow.

The inflow rate applied in the initial portion of the furrow was determined by means of continuity equation, which relates directly the cross sectional area of flow (A) and speed of the flow (v):

The estimation of water speed in the furrow irrigation was carried out from the Equation of Chezy and the speed coefficient by means of the Equation of Bazin (Roldán et al., 1999; Castanedo et al., 2013; Jiménez, 2015).The equations were the following:

Where C is the speed coefficient; S o the slope of the furrow (m m-1) and γ is the ruggedness coefficient of the furrow.

The substitution of the Equation (20) in the (19), an equation that facilitated the determination of the furrow inflow rate was obtained.

Analysis of Estimating the Flow Applied in the Furrow

The results of the methodology application, starting from an irrigation test in which a furrow inflow of 2.24 L·s-1 was applied and top width (T) was measured in the different stakes placed every 20 meters until the total furrow length of 100 m, are presented in Table 3. It is observed that the simulated furrow inflow rate is 2.24 L s-1 and it has a similar value to the applied real furrow inflow rate. This flow was obtained with a value of 3.64 for the Bazin ruggedness coefficient, which is in the range from 1.75 to 4.00, mentioned by Roldán et al. (1999).

TABLE 3.

Value of hydraulic parameters measured and predicted in the furrows

Table 3 shows that the flow diminishes when the advance front moves away from the initial portion of the furrow, what constitutes a normal behavior in this irrigation technique where the flow is variable and decreasing, as the distance increases. This is due to that the movement of the flow is not permanent (slowed) for the fact that the furrow inflow rate infiltrates in contact with the soil for the combined effect of the infiltration rate, ruggedness, furrow form and slope of the plot (Pacheco et al., 2007).

Comparison between real and simulated furrow inflow rate through the Average Percentage Error (APE) demonstrates that the proposed methodology is very exact for estimating furrow inflow rate that is applied in the furrows irrigation. That is evidenced in the fact that the APE obtained a value of 0.00% that indicates the absence of differences between both inflow rate.

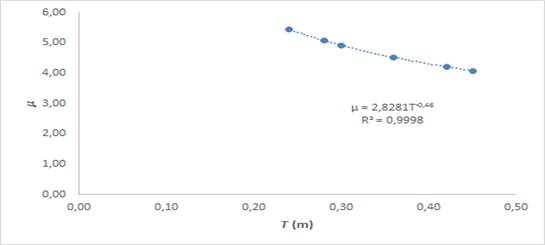

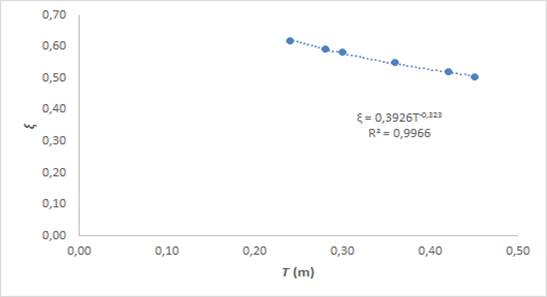

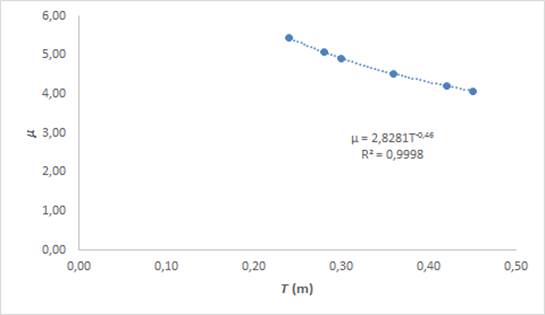

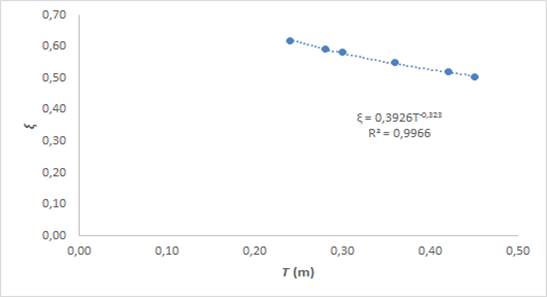

Functional relationship of the coefficients µ and ξ respect the top width is presented in Figures 2 and 3. The values of coefficients µ and ξ oscillated from 4.08 to 5.45 and of 0.51 to 0.62, respectively. In both cases, a simple potential model was achieved with high coefficients of determination of 0.9998 and 0.9996, respectively. That validates its sure application in the estimation of these coefficients for the calculation of cross sectional area of flow, the corresponding hydraulic radius.

FIGURE 2.

Curve of coefficient μ respect top width.

FIGURE 3.

Curve of coefficient ξ respect top width.

CONCLUSIONS

The geometric parameters of the furrow determined experimentally in sugar cane cultivation reached average values of 0.159 m; 0.590 m; 0.032 m and 1.756 for the maximum height of furrow, maximum top width, bottom width and side slope coeficient, respectively.

The simple potential model of type y=e·T f found in the investigation allows estimating, in a reliable way, the flow depth in the furrow from the direct mensuration of the top width.

The values of the coefficients µ and ξ oscillate from 4.08 to 5.45 and of 0.51 to 0.62, respectively. These are of great utility for the calculation of the cross sectional area of flow, only by estimating the side slope coeficient and flow depth in the furrow.

The proposed methodology demonstrated, through the Average Percentage Error, that the simulated flow is similar to the real furrow inflow rate and it confirms its high accuracy.