INTRODUCTION

According to FAOSTAT (2017), the population will increase by 2050 to 9500 million inhabitants. The competition for food between humans and animals will be accentuated, and on the other hand, the negative impact of climate change will increase to make the efficient production of cereals. Food is a chain of events that begin with the cultivation, selection and preparation of food, up to the forms of presentation and its consumption for human feeding and animal production. Pork is one of the most produced and highest per capita consumption in the world, with an estimated production in 2015 and 2016 of around 110 million tons of meat, according to the United States Department of Agriculture. Pig breeding contributes for approximately 37% of the animal protein consumed worldwide (FAO-FAOSTAT, 2011).

The previous situation invites to look for scientific solutions in the tropical and subtropical area where the majority of the developing countries are located. It is necessary to increase agricultural yields, the search for new foods, and the efficient use of these to achieve a better standard of living. At the same time, these so-called alternative foods, generally, when they are extracted from the land and not used rapidly, tend to decompose, causing important losses for the producers (Lezcano et al., 2017).

The productions of roots and tubers in Cuba have been increasing in recent years, according to ONEI (2017), among which the production of sweet potatoes stands out, with continuous growth since 2011, although in 2015 there was a slight decrease, associated with the climatic conditions and the infestation by tetuan. In 2017, sweet potato production increased by 94.67% compared to 2012.

In 2011, Lezcano and a Multidisciplinary Group created an alternative food that they called Cuban Silage Feed (CSF), which, due to its characteristics, is conserved over time and is used with a positive effect in the feeding of pigs. For the above, the following work aims to make the technological proposal to obtain the CSF on an industrial scale.

METHODS

In order to propose the industrial technological process, the background of other agroindustries dedicated to the production of animal feed in Cuba was taken into account with the areas that integrate it. Parr (1988); McEllhiney (1995); FAO (2003), were considered for the selection of the place, norms of security and environmental regulations. Work premises to be fulfilled, the small scale production and the physical properties of the raw materials and the final product were considered according to Silva et al. (2017).

Work premises were established, with the aim of making the new technology sustainable, contributing to the substitution of maize imports, using inactive infrastructures, equipment and national raw materials, obtaining an innocuous product, kept preserved in time and that environmental contaminants were not generated. Other premises are that the pigs had a positive productive response, that the potential capacity of the agroindustries were 45 t / d and that they worked 300 effective days in the year, that they belonged to the AZCUBA Sugar Group and that the percent of exploitation capacity for the agroindustries are 75% the first year, 85% and 90% the second and third year, respectively.

Conception for the Agroindustrial Production of the CSF

The criteria for the industrial proposal and the equipment that make it up, were given by Pahl & Beitz (2013), in terms of activities they perform, production capacity, working conditions, energy consumption, parameters (current, voltage and frequency), safety and protection. Other aspects such as technical-economic efficiency and work guarantee for the environmental conditions of the place were considered according to Paneque (1988).

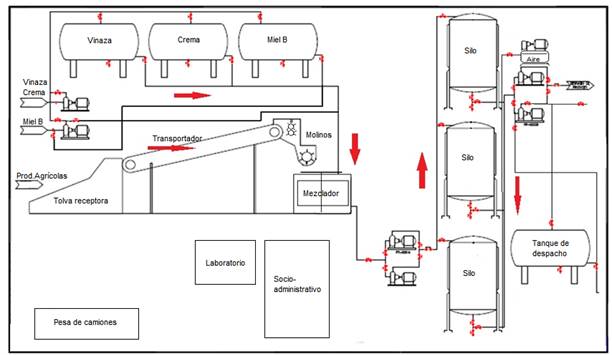

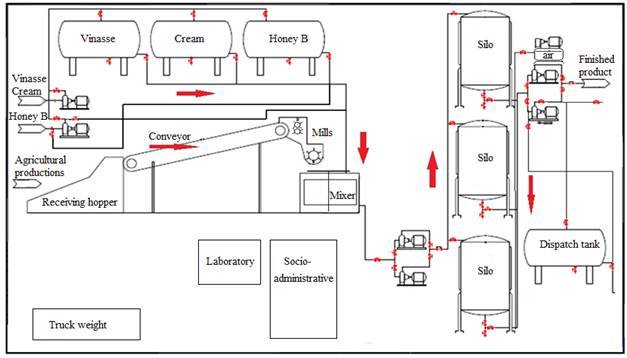

The weighing area is where the transportation means (loaded or not) are weighed; sampling is in charge of verifying the loads (for reception or not) and giving access to raw materials for storage. The transportation and milling area transports the agricultural products from the receiving hopper to the mills to be fractioned and ground to the proposed particle size (4 ± 2 mm); the mixing one , homogenizes all raw materials so there is no accumulation of clumped lumps that hinder the silage process. In the area of the same name, the process of conservation of agricultural products in the mixture of liquids occurs.

The dispatch area is responsible for the output of the final product and laboratory and socio-administrative areas are linked to the quality of the process and the working conditions of the staff.

For the reception of raw materials the criteria of some researchers were taken into account Bates et al. (1995); Khajarern, & Khajarern (1999); Jones (2000) and were carried out if they met the established requirements, guaranteeing daily production and work coverage, with good distribution of space (Brennan, 2006; Oldshue, 2014; Silva et al., 2017).

The storage capacity was selected taking into account the characteristics of the raw materials, the distance of the sources of supplies, the environmental conditions, the levels of access and the availability of automotive transport.

The proposal of the transporter took into account, technical factors, such as productivity of the machine, properties (physical-mechanical) related to the conditions of the load, characteristics of the technological process, direction, length, form of the route that made the load, method in which it was deposited in the conveyor and the conditions of the environment (Paneque, 1988).

Among the criteria for the proposal of the mills were the characteristics of the technological process, productivity (t / h), dosage form, characteristics and particle size to obtain, dimensions and cleaning of the mills (Pahl et al., 2007; Pahl & Beitz, 2013).

For the design of the mixer, the criteria of other researchers were taken into account Brennan (2006) and of Oldshue (2014), which were related to characteristics of the raw materials and the product to be obtained, quantity to be mixed, form and type of dosage; type and proportions of the mixer, agitator to use, speed of agitation and way to drive the mixture to the silos.

The raw materials have different characteristics and unequal proportions within the mixture. The dosage is made by volume, the vinasse and the cream arrive by gravity to the mixer, the honey B is driven by rotary gear pump and the ground agricultural products fall freely by the position occupied by the hammer mill with respect to the mixer. The mixture is driven to the silos with an open impeller centrifugal pump.

The silage process occurs when raw materials are already mixed in vertical silos. The capacity of the silage area is proposed based on daily production and storage coverage. The silos are selected taking into account: their form of feeding, characteristics of the mixture and of the product to obtain, amount of product to be ensiled, time of duration of the process, time in which the final product sediments, method of recirculation and safety of the personnel . The selection of the dispatch tank was made by the characteristics of the CSF, the way of feeding the tank, the established capacity, the time of permanence, homogeneity and safety of the area.

The laboratory with minimum conditions for sampling raw materials, formulation of CSF, analysis for the certification of the product (ρ, pH, SSt, ºBrix) with its procedures, conserves the control samples. A socio-administrative building with office and local to complement other activities and parking area are the areas that are complemented in the agro-industry.

The selection of the pipes, valves and accessories was made fundamentally taking into account the pressures that must be withstood in normal working conditions; the pumping systems for the most critical conditions, according to the characteristics of each product, the flow rates (m³/h) and loads (m.c.a) that are needed from the most distant point, foreseeing how to finish the production process in the event of faults or breakage of some of the systems Perez (1999); the compressor for the extreme conditions and the volume of air that is needed during 15 min to remove the solids from the bottom of the silos. The equipment was driven with three-phase squirrel cage asynchronous motors, with a power supply of 440 v, 60 Hz, taking into account for its selection the characteristics of the environment, the load and the motor.

RESULTS AND DISCUSSION

Proposal of the Agro-Industrial Process

The weighing area has room for operator and arm mechanic weighing machine (up to 30 t), with ball system. It is used in means of transport of up to 15 m length.

Sampling of the raw materials is carried out from the transport means and the yeast cream and vinasse are received from the tank truck that is positioned on the unloading ramp, the agricultural products from the receiving hopper (40 m3) or pallets in bags and honey B from rail hopper with positive displacement rotary electric pump with flow 32 m3 / h.

The storage area for raw materials has 5 horizontal deposits of carbon steel of 33 m3 (diameter of 2.54 m and length of 6.56 m) to store liquids, equidistant from each other (1.30 m above the level ± 0.00 m), with register, vent, valves and carbon steel pipes, all coated in its interior with epoxy paint, two railway hoppers (40 t each) for transfer and storage of honey B and a receiving hopper (inclined 20o) large capacity for 35 t (1.0 m above the level ± 0.00 m), with slat conveyor mat that moves smoothly (0.011 m / s) and without noise, and push attachment across the width. The stamped sheets of steel sheet (thickness 4 mm) are attached to the chains with screws. The storage capacity guarantees the work coverage for 7 days for agricultural products, 7 days for vinasse, 3 days for cream and 18 days for honey B.

The yeast cream and the vinasse have to be recirculated to achieve the required homogeneity; the operation is performed with centrifugal electric pump (BSA 90-10) of open impeller of national production.

The area of transportation and milling with rubber belt conveyor (length 21 m, width 0.7 m) of productivity of 10 t/h, works discontinuously, inclined trajectory (3.3 °) and low speed (0,04 m/s), being less than that recommended by Paneque (1988), to avoid excesses of agricultural products at the entrance of the mill. The load is deposited in bulk and at the end up to a mill of blades (designed in 1973 and modified in 2011) of equal productivity, which has four sets of screwed blades, with possibilities of change and arranged at 90 ° from each other.

Due to the size of the agricultural products, they are chopped to reduce their size (approximately 8 times), to facilitate their entry into the hammer mill, an action that prolongs the life of the hammers due to mechanical wear. The industrial hammer mill (10 t / h), is subjected to a wet milling by the hammers have the edges with cutting edges as blades, which made it possible to grind fibrous and still sticky material (Litster et al., 2004). It is an easy to clean mill, with interchangeable hammers, anvils and screen.

Vertical cylindrical mixer (diameter 4.3 m and height 1.1 m) of large dimensions that mixes 15 t for each volume, was designed with agitator that works with low frequency of rotation (1.39 s-1), centered of pallets in form of grid and baffle plates, which give circulatory movement to the mixture because it generates greater turbulence, which improves the mixing process and the formation of vortices. Construction proposal in carbon steel 6 mm, with flat bottom, which is dosed by volume, is covered – parts of the upper area, with railing and ladder for safe access of personnel, with removable lid to make measurements and take samples of the volume .Two centrifugal pumps of open impeller of national production (BSA 40-15), have the function of extracting the mixture of the mixer and propelling it to the silos. One of the pumps works in an auxiliary way, in case of failure or breakage of the main pump or maintenance of it.

The silage area was proposed with 9 vertical silos, made of carbon steel of 41 m3 (1.25 m above the level ± 0.00 m) each, with filling at the top and conical bottoms with unloading system, all equidistant from each other, coated inside with epoxy paint, with registers, vent, sampling, recirculation and air injection system, carbon steel pipes and flanged guillotine valves. It has an area with air compressor to inject air to the exit valve of each silo, before caking of the solids at the bottom of the silos and two centrifugal pumps of open impellers (BSA 140-25) of national production, coupled to electric motor, for transfer and recirculation of the silage.

The dispatch is carried out from an area that has a carbon steel storage tank, covered in its interior with epoxy paint, arranged horizontally, of 77 m3 (1.0 m above the level ± 0.00 m), with a filling system, registration and vent on the upper part, unloading system, carbon steel pipes, flanged guillotine valves, sampling and safety systems. That operation is carried out with the silage area pumps.

The laboratory was ventilated, with plateaus, water 24 h, shelves and cabinets. With portable digital meter, hand-held refractometer, tabletop centrifuge and digital analytical balance. Socio-administrative area as local infrastructure, with conditions necessary for the proper development of activities, with limited access to the production area.

Technological Process in the Agro-Industry

The agroindustrial process goes from the reception and sampling of raw materials, to the exit of the CSF (Figure 1) and it was proposed taking into account the studies carried out.

FIGURE 1.

Technological process of agro-industry.

CONCLUSIONS

An agroindustrial technology was designed to produce 45 t/d of silage, provided with a sampling, reception and storage system, transportation until milling, mixing and silage, with dispatch of finished product.

With the proposed technology, 11 agroindustries are working in Cuba, with savings due to substitution of maize imports, more than USD 7 million in 5 years and reduction of more than 12,000 t of CO2 to the environment.