On the influence of some agricultural and industrial aspects in the economy, it is necessary to consider the influence that the harvest-transport process has on the quality of the raw material before being processed industrially. It is evident that, although the harvest-transport process does not constitute an element that influences the production process of both cane and sugar itself, it does determine the economy of the production process. This process is developed with the use of a set of technical means, among which harvesters and means of transport (tractors and / or trucks with carts or trailers) can be mentioned and if they are irrationally organized, influence negatively the total production costs.

The introduction of more powerful and reliable machines is important to ensure that sugar industry maintains a leading role in the country's economy. Because of the rapid development of sugar industry, the improvement of equipment systems has continued, specifically in cane harvesters. In order to achieve this objective, it is essential to carry out laboratory and field investigations that enable the design of machines that provide better performance for the sugarcane harvest. The comprehensive studies of evaluations on the machines in development avoid that the errors are generalized and allow decreasing expenses and correcting possible deficiencies of design. Sugarcane harvesting machines have been subjected to various evaluations in order to increase their efficiency and comfort and reduce production costs (Fernández & Álvarez, 1988; Fernandez & Delgado, 1989; Shkiliova et al., 2000; Ortiz-Cañavate, 2003; Shkiliova, 2004; Amú, 2010).

On the rationalization of the harvest-transport process several investigations have been developed, in which different methods based on simulation and mathematical modeling have been proposed. These studies have been carried out with the purpose of determining the optimal use of different means of transport during the harvest of crops such as rice and sugarcane, as well as the determination of the rational composition of the harvest-transport brigade applying the Mass Service Theory. This theory makes it possible to analyze the productive process from the probabilistic perspective starting from the deterministic method (López et al., 2012; Matos & Iglesias, 2012; Matos et al., 2014; Matos et al., 2014; Rodríguez et al., 2015).

In the Business Unit of Base (BUB) “Héctor Molina Riaño”, Attention to Sugarcane Producers, has arisen industrial, organizational and productive problems. Therefore, the harvest-transport process may be affected by the rational composition of the harvest-transport brigade, reducing the stability of the flow of the technological process and increasing its costs.

For this reason, it is necessary to investigate the rational composition of the harvest-transport complex of sugarcane in the BUB “Héctor Molina Riaño”, with the purpose of achieving greater stability and obtaining economic advantages in it. For the above mentioned the investigation had as objective to determine the rational structure of the complex harvest-transport of sugarcane through the model of Markov.

The experimental research program was developed in the BUB "Héctor Molina Riaño", Mayabeque, Cuba; during the agro technical period of the sugarcane harvest in 2017, carrying out the fieldwork and the characterization of the experimental area. Technological and operation evaluations were carried out on two (2) CASE IH AUSTOFT A 8800 harvesters and the mechanized media involved in transport. These means are made up of Belarus 1523 tractors with VTX 10000 self-tilting trailers of 10 t capacity and hauling trucks HOWO SINOTRUK with two (2) trailers of 60 t capacity in total (20 t each).

For the analysis of the rational structure of the harvest-transport complex of sugarcane using Markov Model, it is assumed that it is a stochastic process, since it varies exponentially in time. It is a succession of observations whose values cannot be accurately predicted (Kijima, 1997, 2013, Hermanns, 2002a, 2002b; Bini et al., 2005; Ibe, 2013). For this model, the states considered are sugarcane in harvesting Ec, sugarcane in transportation Et and sugarcane in reception center Er. The amount of transportation means necessary is obtained by the deterministic method and it is combined with the transition probability criteria from the elaborated matrix (Conlisk, 1976; Tijms & Tijms, 1994; Bolch et al., 2006; Ching & Ng, 2006; Sánchez, 2016).

To establish the probability of transition in each state of the ones declared, authors start from the photo chronometry of each process according to Aguilera and Fonseca (2013) and Rodríguez et al. (2015), determining the coefficients of technical availability of the harvesters and means of transport, as it is shown in expression 1.

T0

- total time (useful work) of operation under design conditions, h;

TJ

- total time of stop due to technical problems, h.

In order to form the transition matrix, the probability of transition or non-transition from one state to another must be determined through Poisson table, according to Yesin & Sevostyanov (2014). For this, authors considered the observations made to the line of trucks in the mill and the mathematical hope for the harvest λc and the transport λt (expression 2 and 3) is determined.

For the harvest, it is determined from its coefficient of technical availability:

For transport, its technical availability is taken into account:

Having λc, λt, and K (number of trucks to observe) for the combine and transport, the probabilities of transition can be determined through the Poisson tables.

To determine the probability of transition (Pt) and not transition (Pnt) of the plant, 15 observations were made that were averaged, determining the number of trucks waiting to deliver the product (ncer) and the total number of trucks in the reception center (ntr);

Taking into account the probabilities of non-transition, the transition probabilities can be obtained:

By means of the above, the transition matrix can be determined from one state to another:

Based on the analysis previously carried out, an estimation of the economic impact due to the rupture of the Cpet cycle can be obtained from the determination of the costs for stops in each element of the cycle and the probability of not transiting from one state to another.

Cpc, pt and Pcr

- cost per stop in the harvest, transport and mill reception center respectively; peso / h

With the direct costs of operation, the costs per stop of the combine and transport can be determined:

Cexp

- operation costs, peso / h;

Cdc

-Cost of depreciation of the harvester, peso / h;

Cc

- Cost of fuel consumed, peso / h;

Cl

- Cost of the lubricant consumed, peso / h;

Cmr

-Cost of maintenance and repair operations, peso / h;

Csoc

-Cost in the combine operator's salary, peso / h.

Similarly, the cost of the stopping time of the means of transportation can be determined, using expression 9:

Cdt

- Cost of depreciation of the means of transport, peso / h;

Cmr

-Cost of maintenance and repair operations, peso / h;

Csot

- Cost in salary of the operator of the means of transport, peso / h.

Regarding the costs for stops at the reception center, the salary of the workers linked to the process, the fuels and lubricants consumed in the process, as well as the costs for maintenance and electricity consumed are taken into account as it is shown in expression 9,.

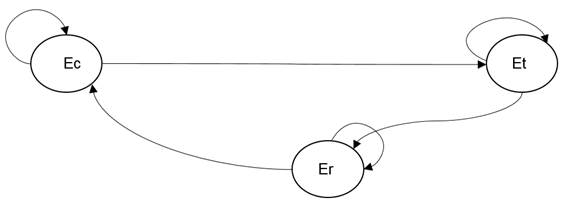

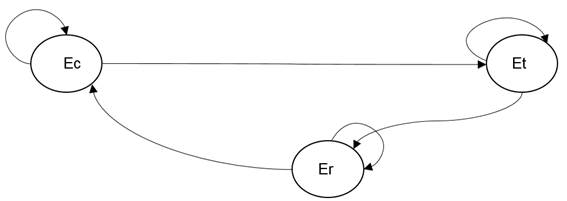

For the realization of the rational composition of the harvest-transport-reception complex of sugarcane using the Markov Model, three (3) states were defined, which were the cane in harvesting Ec, the cane in transportation Et and the cane in reception Er , represented in figure 1 and where the flow of these states is shown.

For the application of this model, lambda values (λ) were determined, which are shown in Table 1, taking into account the technical unavailability of the harvester (1-Kd) and the means of transport (trucks) which were 0.13 and 0.05, respectively. It was also taken into account that there were two (2) harvesters in the sugarcane harvest state, and 2.25 trucks were needed to transport cane, according to the deterministic method, so that there is a cycle in the process harvest-transport-reception. For the state of cane in reception, given the observations made, a transition probability of 0.41 and a non-transition of 0.59 were obtained.

By means of the results obtained, the transition matrix could be formed. In the harvesting state, the transition probability was 0.87 and the non-transition probability was 0.13. Non-transition probability for transport cane was 0.05 and 0.95 for transition. For reception, 0.41 for transition and 0.59 for non-transition as shown in matrix 10.

While analyzing the previous results, and determining the probabilities through the Poisson tables, as shown in Table 2, it is obtained that the probability of non-failure or breakage of none of the harvesters is 82%. The probability of a failure in at least one (1) is 16.37%, which makes it possible to foresee the effects it will have on the cycle due to the stoppage of a harvester. When analyzing the case of trucks, it is obtained that the probability of failure or breaks of any truck is 95.12%, and that there is a failure in at least one (1) of 4.76% decreasing to 0.12% of breaking two (2) at the same time.

As mentioned above, the deterministic method showed that 2.25 trucks are needed for the existence of a cycle in the process. Therefore, taking into account the low probability of breakage of at least one harvester and / or truck, it can be assumed that the brigade, for the agricultural yield of 22.8 t / ha will be made up of two (2) harvesters with two (2) moving tractors and two (2) trucks for the transfer to the plant. Since the filling time is 2.66 h and the cycle time of 4.94 h, the probability that the harvester waits for external means of transports is almost null.

From the transition matrix, the cost can be determined if the transportation cycle is stopped in the states declared (Ec, Et and Er) of the process, obtaining a cost of 10.73 pesos / h, when the sum of stop costs in the states considering the probability of non-transition amounts to 5.29; 0.82 and 4.62 pesos / h, respectively. However, as the probability of non-transition was not taken into account, a cost per plant stop of 7.84 pesos / h, a cost per harvest stop of 45, 47 peso / h and transport stop of 16.56 peso / h were obtained.

Markov Model showed that for a field with a yield of 22.8 t / ha the brigade will consist of two (2) harvesters and (2) two means of transport, since the probability that the harvester waits for means of external transport is almost null, being the expense per cycle stop (harvest-transport-reception) of 10.73 peso / h.

Markov Model allows defining the rational conformation of the harvest-transport-reception brigade from another model or method that proposes possible compositions.